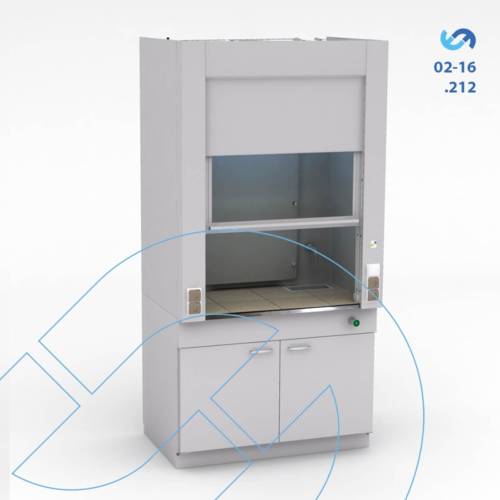

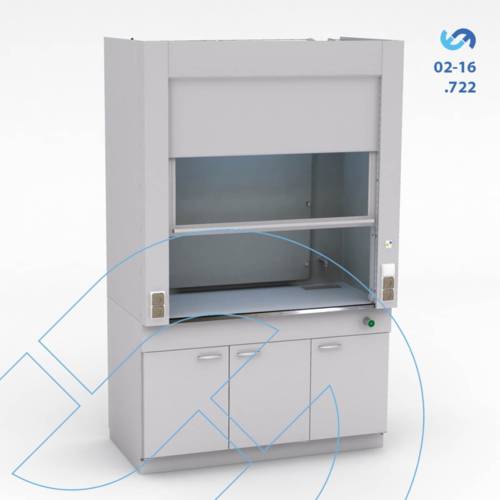

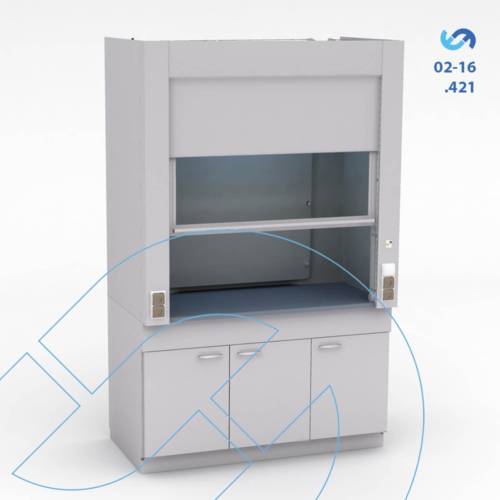

Features:

- a reliable powder coated metal frame guarantees high reliability of the construction;

- light grey powder coated sheet metal;

- a counterbalanced lifting sash made of Triplex Safety Glass can be fixed at any height required (50 - 650 mm);

- one-piece fibreglass lining of working area resistant to corrosives and high temperatures;

- a 250mm diameter flange for ducting system connection is installed in the upper section of the cabinet;

- lighting with 2 fluorescent lamps is installed for illumination of the working place;

- underbench unit with 2/3 sections, each with a door and is equipped with adjustable interior shelf;

- levelling feet to compensate for floor unevenness.

Configuration:

- 4 Schuko sockets (220V, with IP55);

- circuit breaker 16A with a transparent protective window (IP55);

- light and fan switch (optionally);

- 1500mm-long electrical cable and Schuko plug;

- polypropylene or Durcon drip-cup is installed as a standard at the right;

- cold water tap with front panel FAR (Italy);

- 1300mm-long flexible polypropylene pipe for waste water connection;

- 800mm-long copper pipe for water supply connection;

- ‘Y’ Type strainer;

- 1/2 vented all-metal underbench cabinets for the storage of noncorrosive reagents;

- left section of the underbench cabinet for the storage corrosives is vented and has a one-piece fiberglass

lining; - concealed hinges placed out of the storage area;

- installation of an air flow monitor.

Optionally:

- installation of a rod latch lock;

- installation of gas/water taps with copper pipework;

- installation of an airflow controller;

- installation of a sash electric actuator;

- installation of a damper with electric actuator;

- installation of an airflow variator for fan control.